Solar Panel Servicing and Maintenance

Maintaining and and servicing the solar panels with a focus on maintaining safety and operational efficiency.

- Regular maintenance of photovoltaic solar panels

- Panel repair and replacement

- Maximising the lifespan and generative capabilities of the panels

- Ensuring the safe functioning of panels and related systems

As a forward-thinking, environmentally conscious local authority, Waltham Forest Council has consistently strived to implement sustainable processes and practices throughout the borough. Not only did it set up London’s first Climate Emergency Commission in a bid to become a net-zero borough, but it has also installed solar photovoltaic (PV) panels at 1,106 locations since 2011.

As a trusted local authority partner, Aston Group was awarded the contract to maintain and service the borough’s panels in April 2012, with a focus on maintaining safety and operational efficiency.

The Challenge

The challenges encountered by Aston Group while servicing and maintaining the PV systems typically related to issues that occurred after the panels were installed. These included:

- Birds nesting underneath solar panels

- Inverters failing to convert direct current (DC) power to alternating current (AC)

- Generation meters not connecting remotely

- Roof anchors not being secure

- Roof leaks

- Damaged panels

- Earth faults on the panels (DC ground faults)

Each of these issues can result in system downtime, which means electricity is not generated. It is therefore vital to identify and remedy the issues as quickly and efficiently as possible while minimising their impact on the borough’s residents – especially as the cost of energy continues to rise.

The Solution

The maintenance programme devised and facilitated by Aston Group goes beyond a standard PV service. It ensures that Waltham Forest Council’s solar PV installations are serviced every 3 years to maintain safety standards and peak productivity.

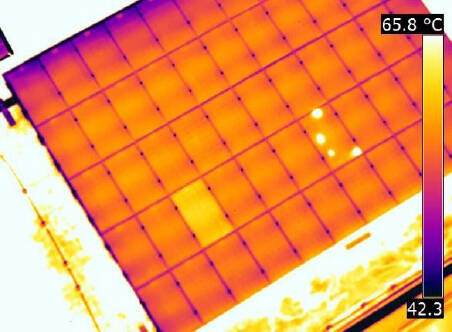

Thermal imaging: DC ground faults are the most common type of fault in PV systems but typically go undetected because they can only be seen with a thermal imaging camera. A DC ground fault sees current flowing through the equipment’s grounding conductor in the circuits carrying DC power (panels).

Below is an example of 2 different faults within a PV array. The images show that the temperatures generated by the equipment exceed manufacturer recommendations. If left unfixed, they could result in a fire.

The image below was taken using the same make and model camera for a test property in Waltham Forest:

Fault 1) The panel is not functioning, either because of mis wired panels or worn and defective cables. This condition is indicated when the entire panel is hotter than those around it.

Fault 2) Delamination due to external damage or substandard solar panel quality. The protective layer on a panel may delaminate, or micro-cracking and cell rupture may occur during transportation or installation as a result of physical stress. Although micro-cracking is not critical, cell rupture (Fig. 6) can reduce performance.

Moisture seeping into the panel may also lead to cell corrosion and loss of performance. Thermal cameras can detect this before the panel’s outer layer shows a “milky” appearance.

This panel was replaced and sent to the manufacturer for research purposes.

Panel Cleaning: We thoroughly clean all panels during the servicing process. To demonstrate the benefits of cleaning, we conducted a study between 2 neighbouring properties with identical systems. We concluded there was an increase of 4-8% in generation between the cleaned and non-cleaned panels.

The PV maintenance regime includes:

Bird-proofing

We remove all solar panels and clean underneath each of the installed systems. We then replace the roof anchors and rails (as these are single-use items) and reinstate the panels with bird-proofing measures which stops birds nesting beneath the system.

Inverter Replacements

The majority of inverters fail within 7 years of installation because that is the expected maximum lifespan of their electrolytic capacitors. With careful planning, we ensure the inverters, are replaced at the point of failure, carefully factoring in any import tax and lead times.

Generation Meter Replacements

During the original installation, up to 10 wireless meters were connected to one Local Data Concentrator (LDC), which reports back to an online portal. If the LDC went down, Waltham Forest couldn’t provide readings for any of the wireless meters connected to it. It also meant that if there was a system fault with any one of these properties, we would not be aware until the LDC was back online. We replaced the original system with the latest smart meters so that each property’s meter could report back to the online portal independently, providing a consistent flow of information.

Anchor Replacements

During the course of the maintenance visit, our engineers identified that some of the anchors connecting rails and panels to roofs were not securely attached. The solution was to replace all of these during the bird-proofing process.

Roof Leaks

Where PV systems were installed, we sometimes found roof leaks where anchors had not been attached properly. We removed the panels to fix the roof leak before installing a new panel-mounting system.

Damaged Panels

Sometimes a system would report that there was no power generation, which meant DC power was not being generated by the panels. This would be due to one or more of the panels being damaged. Often this was caused by birds. We replaced the panels, mounting them and installing bird-proofing devices to stop this happening again.

The Results

As a result of the robust service and maintenance programme conducted by Aston Group, Waltham Forest’s solar panels have yielded impressive figures.

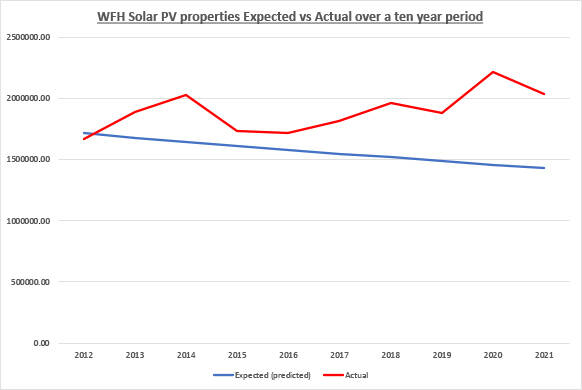

Initially, following the installation of the photovoltaic systems which started in 2012, the electricity output was in line with the predicted energy outputs. Estimates stated that 13,961,948.06 kilowatts would be generated in the first 9 years.

However, thanks to extensive maintenance and servicing programme, the actual figure was 17,266,300.60 kilowatts. This is over 20 percent more than anticipated.

In turn, this equates to an additional saving of £687,305.33 for Waltham Forest residents, on top of the savings predicted (based on energy prices in July 2022).

The Borough of Waltham Forest also benefitted from the feed-in tariff and deemed exports back to the grid. The service and maintenance activity directly led to an extra payment of £1,000,888.38 at an average of 28.13 per kilowatt generation and 4.32 pence per 50 percent deemed export. Consequently, there has been a total additional financial benefit to the Borough of £1,688,193.72.

It’s worth noting that, for most PV systems, electricity generation decreases over time. However, as can be seen in the chart below, the thorough service and maintenance regime conducted by Aston Group has resulted in a continuous average increase in generation over the years. This is despite the system having a 2% reduction in efficiency each year, along with downtime for repairs and replacements. This improved performance ensures that the borough will continue to save money on electricity used and generate income for many years to come

- £1,688,193.72

- Total additional financial benefit to the Borough

Total expected generation against actual generation across the Borough of Waltham Forest. Data reference: As per www.sunrise-portal.com/tv/ download to PV 2022.CSV

“At Waltham Forest, we want to lead the way for other boroughs in reducing carbon emissions, not just for London but across the whole of the UK. Working together with Scott and his team over the years has resulted not only in a huge reduction of carbon but also the added benefit in fuel bill savings to our residents too.”

“It has been an absolute pleasure to work with Waltham Forest Council over the years. It’s an exciting time for the renewables industry and it was fantastic to help support the local authority in taking the next steps towards achieving its net-zero ambitions. I can’t wait to see the energy reduction figures continue to reduce and Waltham Forest’s positive impact on the environment.”