Leisure Centre Boiler Plant Upgrade

Refurbishment of basement plant room area to include upgrading of mechanical equipment, controls and gas supply.

- Replace the boiler plant to provide an environmentally friendly heat source

- Avoiding the need to use a temporary boiler plant by continuing with the project during lockdown

- Refurbishment of basement plant room area to include upgrading of mechanical equipment, controls and gas supply

- Removal of all redundant equipment

- Extensive asbestos clearance.

The original boiler plant at Blackshots Leisure Centre, which provided its heating and hot water, was at the end of its life. One boiler was now defunct, and the original pipework and electrical installations were inefficient and in a poor state of repair.

Thurrock Council, through consultants Beveridge Associates, issued a tender for the replacement of the boilers, associated pipework and controls, to bring the plant up to both efficiency and environmental standards. After a competitive and challenging tender process, Aston Group was appointed to undertake the project.

This exciting but challenging modernisation project commenced on the agreed date of May 4, despite the leisure centre being closed due to the Covid-19 lockdown. The first challenge was to implement a social distancing regime to be placed throughout the works. This was achieved by producing a programme to phase the works, preventing different tradespeople from being on site at the same time wherever possible. We also appointed one of our many experienced site managers to engage with all the stakeholders and ensure compliance.

Once the primary circuits had been isolated and drained, the mechanical team marked the items that would need to be safely removed. Then the asbestos removal contractors took over the site for five weeks to undertake all the removals and scraping of the walls and ceiling, followed by encapsulation of the plant area. We also asked them to attach unistrut rails to provide fixings for all our pipework and electrics, negating the need for possible disturbance of asbestos residue during both this and any future works.

To ensure the programme was kept on track, instead of casting one long concrete base for the new plant, two smaller bases were cast; this saved both time and materials.

The new boilers had originally been planned to be delivered in sections, then manually positioned in the plant room for the boiler manufacturer to assemble on site. To reduce the time this element would take, it was arranged for the boilers and associated plant to be lowered into the plant room fully built; they were therefore able to be positioned on the new concrete bases in a single day.

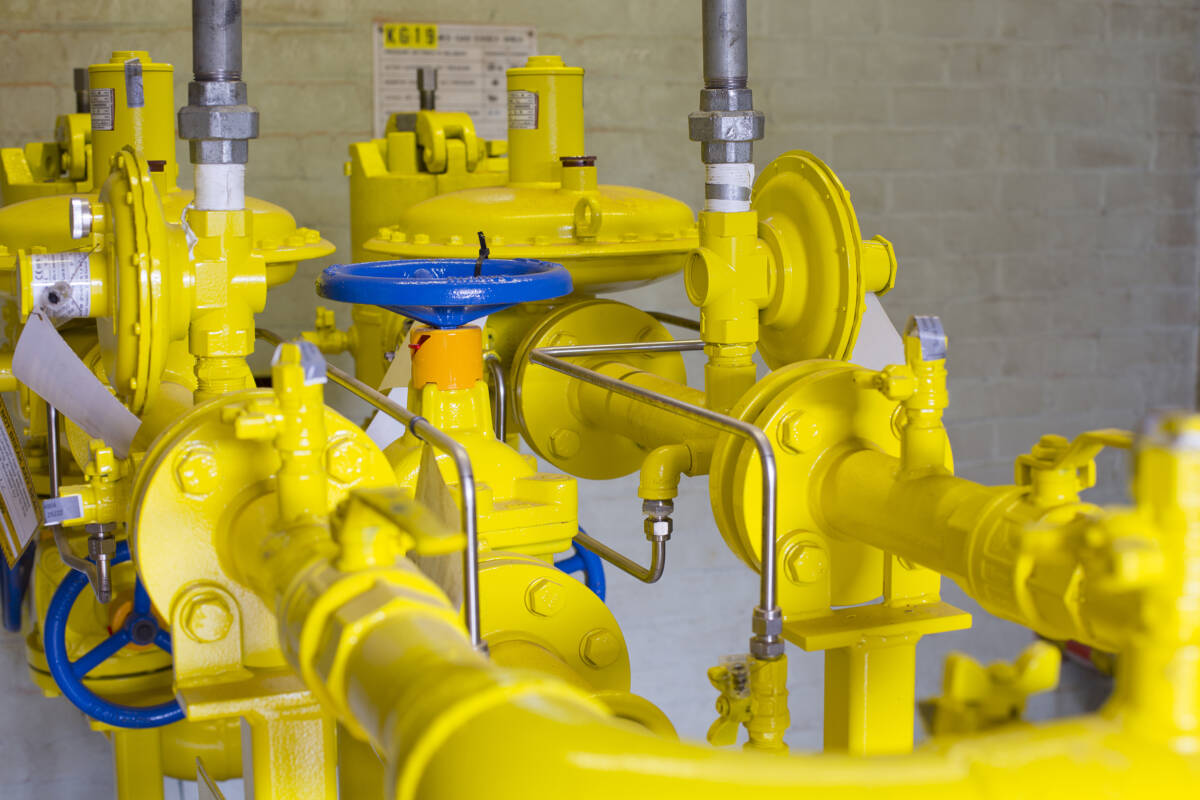

The internal plant and pipework installation was straightforward for our experienced team; the planning and layout was adapted from the initial design drawings, and the final product was a neat and tidy standard Aston Group installation. All the new pipework was thermally insulated and protected with aluminium stucco sheet, valve jackets and appropriate identification.

There were difficulties in routing the new gas supply into the basement plant room through the building’s concrete footing, so we installed the last section externally and entered the building through the now-redundant fire foam suppression hatch that used to serve the original oil boilers. As an additional safety feature, we fabricated and installed bespoke bollards as protection.

Both the council and the leisure centre were delighted with Aston Group’s work on this contract, as evidenced by the testimonials below:

“Thurrock Council was impressed by Aston Group’s commitment to the project during the Covid-19 lockdown. This, together with collaborative working between the whole team … ensured that delays were minimised and costs came in within the original budget.”

“We found the Aston Group team very informative and supportive. All the installations were completed to the expected high level of finish with professionalism – even with the ‘curve ball’ of Covid-19. We would happily recommend Aston Group and hope to work with them in the future.”